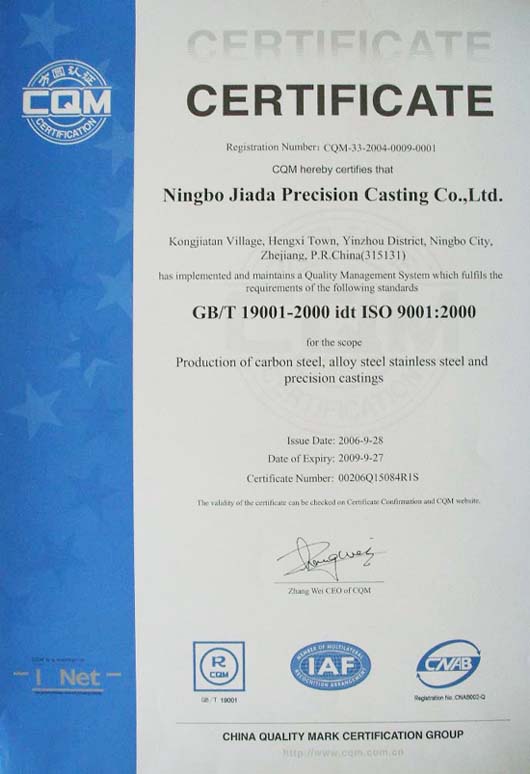

OUR QUALITY MANAGEMENT SYSTEM

ISO 9001:2000 CERTIFIED

PROTOTYPE CONFIRMATION FROM CUSTOMER

- Before high volume production, we send prototype to customer for confirmation. Then seal the confirmed samples as the quality audit reference.

ADVANCED QUALITY/PRODUCTION PLANNING

- A Part Control Plan is generated for each part manufactured identifying all key product characteristics and defining the methods for their control.

- A Process Flowchart is generated and defines the manufacturing process as well as the interaction and controls throughout the product realization.

- Process Failure Mode & Effects Analysis is performed to assure the prevention of defectives through the manufacturing process.

- A Full Metrology Review of the key parameters is performed and methods established to assure design intent is met.

- A Full Dimensional Layout is performed to verify mold design and part print compliance in the pre-production phase.

MEASURING EQUIPMENT

- Spectrometer for Spectrographic Analysis of Alloy, Metallurgical Microscope for Microstructure Analysis, Universal Mechanical Property Tester for the Tensile/Yield Strength, Elongation Analysis.

- 2-Coordinate Measurement Machines for full dimensional layout

- Field Manager for real-time monitoring and analysis of key process parameters

- Standard calibrated instruments used throughout industry to verify key product characteristics

QUALITY CONTROL

- Part Qualification: First-Piece Inspection at the start of each production run

- Variable and Attribute Control Charting during the production run

- Part Evaluation: Last Piece Inspection at the end of each production run

- Final Audit: Random sampling of each ship lot for compliance of key characteristics

QUALITY ASSURANCE TEAM

- Experienced and dedicated engineers in Quality Engineering, Quality Auditing, Quality Technology, and Mechanical Inspection

- Our cross-functional approach to Quality is personified by Product Control Teams

- Internally Certified Operators demonstrate our commitment to Continual Improvement

|